Sovereign touts Malingunde as World’s largest

By Gloria Mbwana

ASX-listed resources group Sovereign Metals, which is prospecting for flake graphite at Malingunde in Lilongwe, has described the resource as the world’s largest reported soft saprolite-hosted graphite Mineral Resource.

Sovereign says in a press statement announcing an updated mineral resource estimate(MRE) for Malingunde that metallurgical test work has confirmed that a blend of saprock can be processed along with the soft saprolite material which enables the company to access additional soft material to that considered in its 2017 scoping study.

The ability to process a blend of saprock along with the very soft saprolite allows a~ 60% increase in high grade, low-cost material that Sovereign will consider as part of Malingunde pre-feasibility study. With this exceptional resource base, the company will now progress rapid completion of the PFS, leveraging the project’s inherent low operating capital and high margin potential,

says MD for Sovereign Metals Julian Stephens.

He says the updated mineral resource estimate provides the basis for a future low capex and low opex natural flake graphite operation focused on the soft saprolite (clay)-hosted component.

Saprolite-hosted graphite deposits are sought after as they generally have lower capex requirements and low operating costs compared to hard rock graphite mines.

Stephens explains that Malingunde has the potential to be a world-class asset with the potential for low capital requirements, low operating costs and high revenues per tonne of concentrate, likely resulting in a high margin operation.

The metallurgical studies indicate that 81% of the total Mineral Resource (>4.0% TGC) and 88% of the high-grade (>7.5% TGC) component is now classified as Measured or Indicated.

There is also a high-grade component of 14.5Mt @ 9.7% TGC (saprolite + saprock) to provide the focus for the Malingunde pre-feasibility; a significant increase in tonnage driven primarily by inclusion of saprock material.

Metallurgical test-work confirms that the blended saprolite (~85%) and saprock (~15%) material does not require primary crushing or grinding, providing the potential for substantially reduced processing costs compared to hard rock deposits.

All planned mining inventory is within 35m of surface and will be free-digging with very low strip ratios, with the potential for very low mining costs.

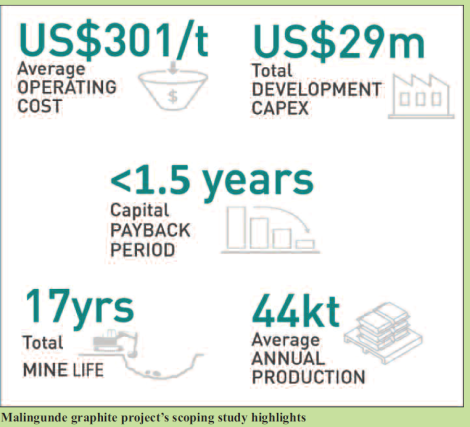

Sovereign Metals is pursuing the Malingunde Project through its wholly owned subsidiary, Mc Court Mining and studies undertaken to date indicate that the resource can yield approximately 44,000 tonnes of graphite concentrate per annum over an initial mine life of 14 years.

The company is also conducting environmental and social impact studies which include community consultations with local stakeholders on the way forward for the project.

Sovereign aims to complete all studies for the project towards the end of 2018 to decide whether the mine will be developed or not in 2019.

The primary end market for flake graphite is the refractory, foundries and crucible sector which consumed approximately 616000 tonnes of flake graphite in 2016.

The majority of flake graphite is used to produce magnesia -carbon bricks used in the steel industry and a growing use of graphite is in the production of rechargeable lithium-ion batteries for laptops and cellphones.

Substantial increase in demand for graphite is also expected in the future for the growing electric vehicle market.

***

This piece was initially published in Malawi’s Mining & Trade Review Issue Number 64 (August 2018).

The full edition is available for download here. This monthly publication is edited by Marcel Chimwala.